Our Products

ABOUT HANDEE

The Handee Cheese Cutter was first manufactured by Digby & Nelson Ltd. In 1947 in Greenford, Middlesex. The company quickly flourished and sales grew throughout the UK, as well as internationally. Handee Cheese Cutters are now stocked by most UK supermarkets as well as being available throughout the United States, Europe, Asia and Australia.

The Handee cheese cutter is one of the most popular cheese cutters in production today. It provides a simple and economical method of cutting blocks of medium to hard cheeses and ensures an accurate and smooth cut.

The cutting boards are strong and durable and are designed to be long lasting (wires and other consumable parts must be replaced). They are safe to use and give a perfect cut with no wastage.

We offer both the plastic and stainless steel versions of the ‘Handee’ cheese cutter along with all necessary replacement parts (which are designed exclusively to fit the Handee cutter).

Our Products

OUR CHEESE CUTTERS

Our Handee cheese cutters have a robust design to give years of trouble-free, accurate cutting. Available in plastic or stainless steel.

Handee Plastic Cheese Cutter

- The ‘Handee’ cheese cutter cuts cheese quickly, neatly and economically with no crumbling or waste.

- Made from one piece of food-grade white melamine, it is completely resistant to chemical action from cheeses.

- It is hygienic, durable and safe to use, with a base size of 33cm x 28cm.

- The stainless steel patented floating wire (60cm) slices smoothly through all type of cheese and returns to cutting position after each cut.

- When not in use, the handle is housed in retaining slots, where the wire is kept semi-taut and free from kinks.

- Replacement wires fitted in seconds.

- To clean, simply wipe down with a wet cloth.

- Comes complete with a pack of 12 replacement wires.

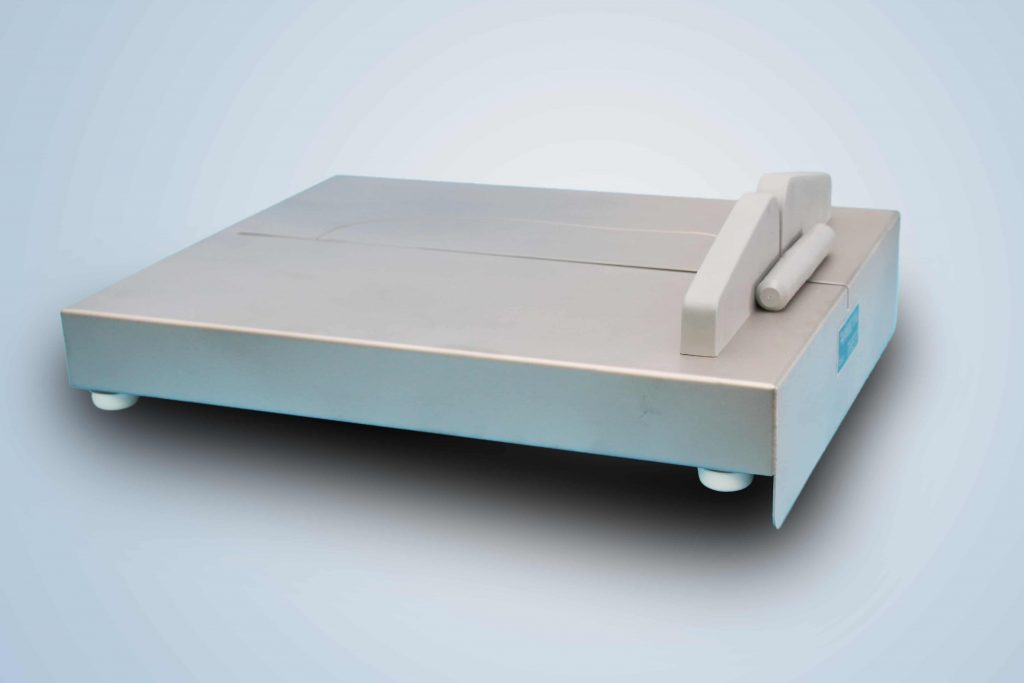

Handee Stainless Steel Cheese Cutter

- The ‘Handee’ cheese cutter cuts cheese quickly, neatly and economically with no crumbling or waste.

- Made from high quality food-grade stainless steel, it is completely resistant to chemical action from cheeses and designed to withstand heavy duty use.

- It is hygienic, durable and safe to use, with a base size of 33cm x 28cm.

- The stainless steel patented floating wire (60cm) slices smoothly through all type of cheese and returns to cutting position after each cut.

- When not in use, the handle is housed in retaining slots, where the wire is kept semi-taut and free from kinks.

- Replacement wires fitted in seconds.

- To clean, simply wipe down with a wet cloth.

- Comes complete with a pack of 12 replacement wires.

Our Products

CHEESE CUTTER ACCESSORIES

2 Handles and 2 wires

- Constructed from polypropylene with brass inserts and complete with a 90cm food-grade stainless steel wire.

- Designed to last for years

- Perfect for cutting whole round cheeses.

Pulley Wheel

- Designed exclusively for both the plastic and stainless-steel ‘Handee’ cheese cutters.

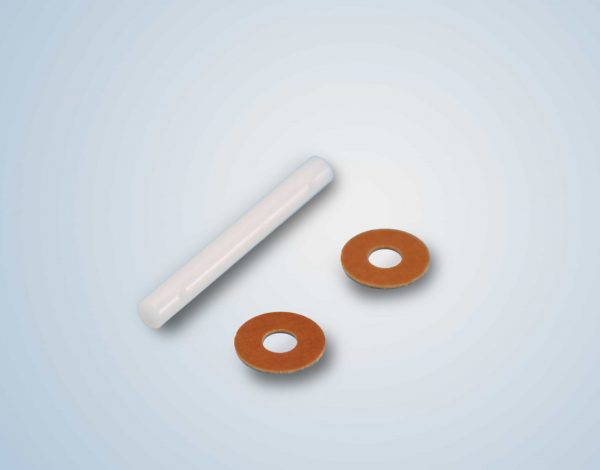

Replacement Handle

- Designed exclusively to fit both the plastic and stainless steel ‘Handee’ cheese cutters.

- Available in grey, white and blue.

- Measures 10cm x 1cm

Spindle and Washers

- Designed exclusively for both the plastic and stainless-steel ‘Handee’ cheese cutters.

Replacement Rubber Feet (x4)

- Pack of 4 food-grade rubber feet with stainless steel screws.

- Designed exclusively for both the plastic and stainless-steel ‘Handee’ cheese cutters

Replacement Stainless Steel Springs (x2)

- Pack of 2 replacement food-grade stainless steel springs.

- Designed exclusively to fit both the plastic and stainless steel ‘Handee’ cheese cutters.

Stainless Steel Replacement Wire 60cm (x12) Standard length

- These spare wires cut cheese with a smooth, easy action.

- Sold in packs of 12 wires.

- Other available size: 31cm, 45cm, 90cm, 115cm.

- We can also manufacture any required length please contact us for details.

- Manufactured from high quality food-grade stainless steel.

- Designed exclusively to fit the ‘Handee’ cheese cutter.

Multi-stranded wires are available but not recommended for S/S cutters.

INSTRUCTIONS ON HOW TO USE

TO USE THE MACHINE

CHEESE

MULTI-STRANDED CHEESE WIRE

HARD CHEESES

TO CLEAN THE MACHINE

HANDLES

CUTTING A WHOLE CHEESE

Got a question about our Handee cheese cutters? Get in touch with us and we'll be happy to help.